Closing the loop on lithium-ion batteries

The hunger for rare earth metals

A problem that cannot be ignored

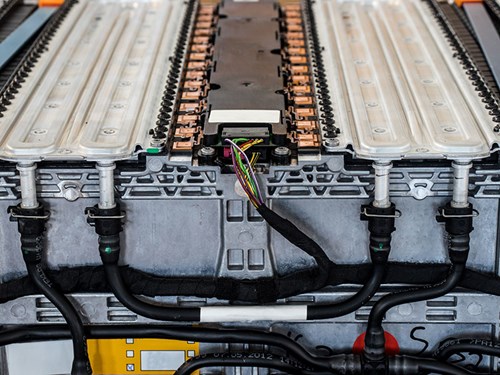

The current world supply of rare earth metals is not sufficient to deliver the change from the internal combustion engine, let alone the growth in consumer products that require ever-more portable and powerful batteries.

Leading scientists at the Natural History Museum recently calculated that meeting only the UK's targets for electric cars by 2050 would require nearly twice the world's current output of cobalt and a 650% increase in lithium output by 2027.

With no efficient method to recycle all the metals in lithium-ion batteries, most are lost at end of life.

Irreversible destruction of our environment

To meet future demand, mining companies are now investigating deep-sea strip-mining as the next source for raw materials.

Meanwhile, existing solutions to recover rare earth metals from waste batteries use high temperature separation or acid extraction - environmentally unfriendly and hazardous processes yielding poor recovery rates.

A viable, environmentally friendly and commercial solution to recover and reuse these rare earth metals must be found soon to meet future demand and to help limit further irreversible damage to our environment.

CellMine - the innovative solution

A disruptive recycling technology

The CellMine process is a disruptive technology in battery recycling, able to selectively target and recover the vast majority of high-value and high-volume metals within a lithium-ion cell, including cobalt, lithium and manganese.

The process is environmentally friendly, low-impact and low cost, ultimately helping to enable the future of lithium-ion battery manufacture in the UK.

£0.5m Innovate UK next-stage funding

On completion of the initial proof-of-concept project funded by Ecosurety in 2021, CellMine secured £0.5m funding from Innovate UK to expand the research for a further 18 months, to explore the commercial application of the process and scale it from the laboratory to a pilot plant.

Partners working with Impact Solutions on the next stage of the project include St Andrews University, a world leader in cathode research, who will test and validate the recyclate resulting from the CellMine process for use in new real-world batteries. Ecosurety is also a project partner who will assist in developing supply chain and feedstock relationships.

About Impact Solutions